Strong laser machine mainly processes transparent and brittle inorganic materials such as protective glass cover plates, optical crystal cover plates, sapphire lenses, camera filters, and optical crystal prisms.

In the field of consumer smart terminals represented by smart phones, smart watches, and tablet computers, inorganic optical materials are very common as the main material for structural design. Specifically, they include a front display panel protective cover and a rear battery cover. Camera/fingerprint recognition sensor cover, power/volume key cover, filter/prism lens in camera module, etc.

From the point of view of these optical materials, they include high alumina glass, sapphire, ceramic crystal, quartz crystal, semiconductor compound crystal, etc.

The non-contact laser processing technology developed by Strong Laser has a very significant advantage for the processing of various shapes of these optical material components. It can completely avoid secondary pollution and physical damage to the inner and outer surfaces of the optical crystal during the processing process.

Among the processing technologies for processing these optical material components, Strong Laser has laser cutting, laser chamfering appearance molding processing technology, laser marking, laser groove surface etching process, and laser internal focusing cutting process.

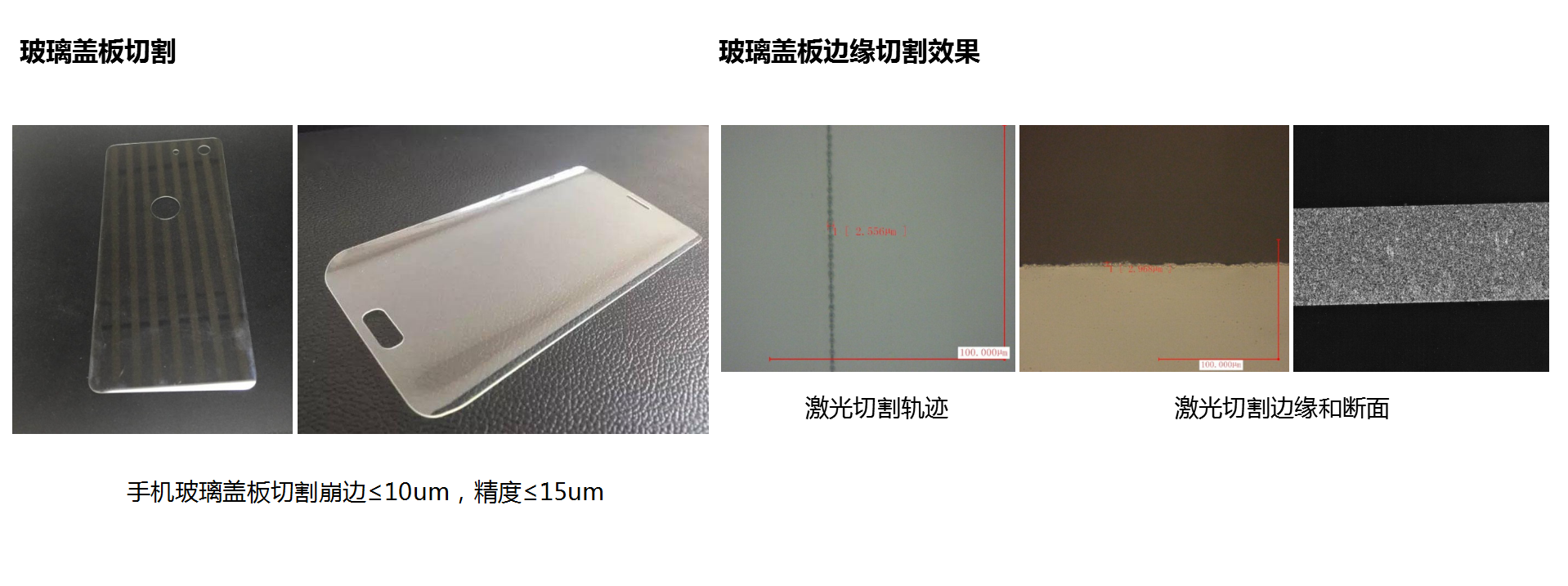

Regarding the laser cutting processing solutions for inorganic brittle optical materials such as glass cover plates, Strong Laser uses ultra-fast laser cutting heads and Bessel laser beam shaping cutting technology. The laser forms a certain depth of internal burst zone inside the transparent material. The stress in the burst zone spreads to the upper and lower surfaces of the transparent material, and then the material is separated by mechanical or CO2 laser.

Compared with the traditional CNC cutting process, the cutting of Strong Laser has the following advantages: narrow cutting seam, less deformation of the work piece; non-contact processing, no stress damage; high-speed special-shaped cutting, direct penetration, high efficiency; no cutter wheel Wear of grinding head, no debris and oil, clean processing, etc.

Main equipment:Strong laser cutting machine for glass with automatic loading and unloading

For engraving and marking solution,Strong adopts femtosecond laser coloring process to realize the processing of dark markings inside the glass without damaging the structure of the material. The main principle is to focus the femtosecond laser inside the glass and select a light intensity below the material damage threshold, so that the glass will change the absorption coefficient and refractive index of the glass material irradiated by the laser, resulting in darkening or discoloration. After multiple femtosecond laser irradiation (scanning), the irradiated part of the glass becomes deeper and finally stabilizes.

Strong laser engraving and marking solution wouldn’t damage the surface of the glass and the glass wouldn’t appear micro-cracks, so it wouldn’t affect the original strength and product quality of the glass; at the same time, this processing technology wouldn’t change the chemical composition of the glass.

The strong laser engraving and marking solution has successfully realized the laser engraving and marking of online product codes and shipping product codes.

Main equipment:Strong laser fiber marking machine、Strong laser ultraviolet marking machine

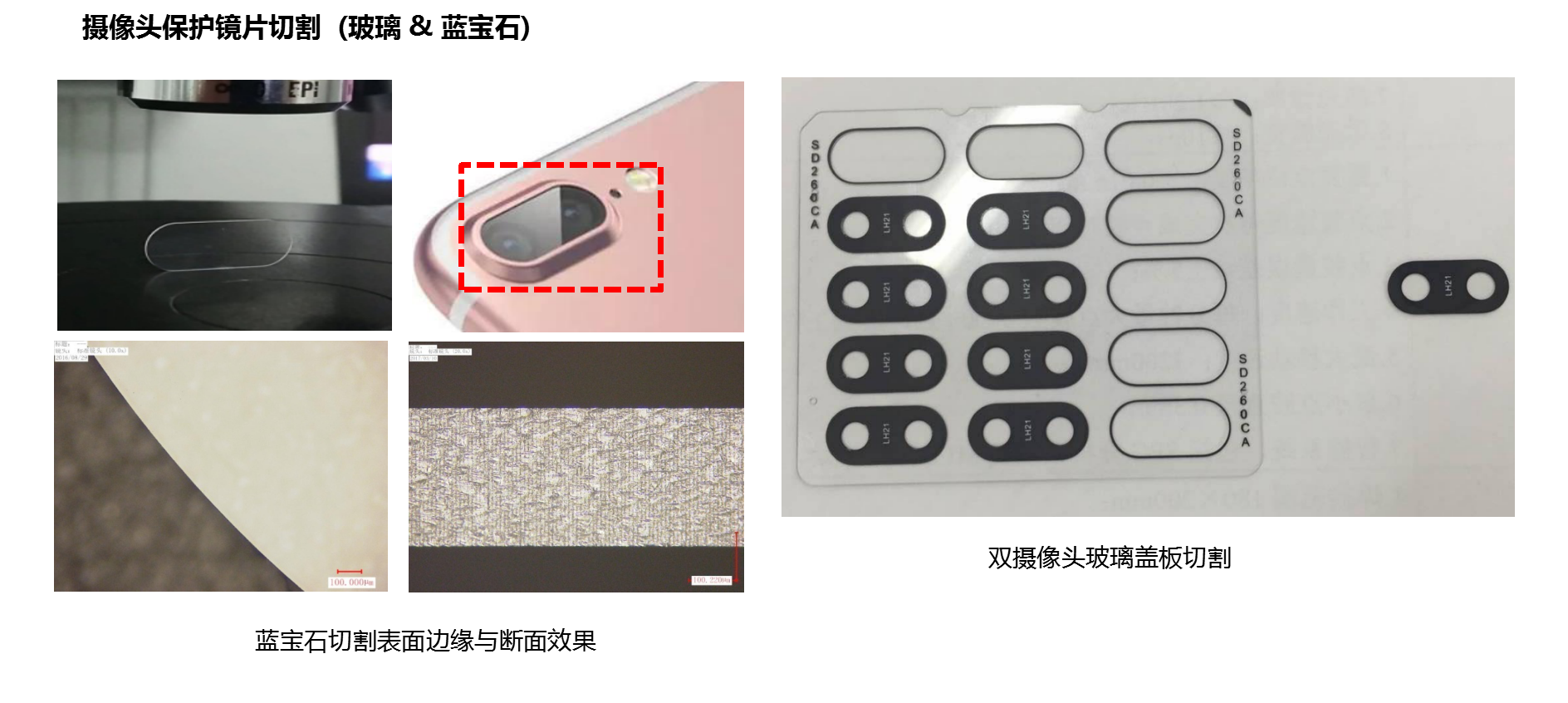

The Strong laser cutting machine for camera/watch cover is specifically for this solution. According to the principle of ablation cutting on the surface, the high-peak power laser beam is focused on the surface of the material, and its surface is repeated repeatedly to be ablated. The material is instantly heated by the high-density, peak and high-power laser, and the temperature rises rapidly to the vaporization temperature. Then the material is gradually ablated by the laser and escapes in the form of gas, so as to realize the cut-through separation of the material.

Main equipment:Strong laser cutting machine for glass with automatic loading and unloading